Can you make it shine? YES! BUT FIRST YOU NEED TO UNDERSTAND THE PROBLEM AND YOUR OPTIONS

In 2002 I returned from a 3 year overseas tour. I started my new job as a flight instructor and I started back into my old ways of hunting, fishing, and tinkering with guns. My dad, ever so generous, gave me a muzzle-loader he picked up on the cheap. Remington made a muzzle-loader based off of their bolt action center-fire model 700. The blued steel version was called the 700ML. The stainless version, sometimes called the magnum, was the 700MLS. The benefits of converting a center-fire design to a muzzle-loader were obvious to me:

- Center-fire rifles typically have faster lock times

- It could use standard Remington 700 short action rings and mounts, and some other accessories

- It had a good trigger (for a factory rifle)

- It resembled the bolt action rifle I used the rest of the deer season

- The safety was in the same spot.

- The stock was pretty much the same

- Though it was a single shot, the bolt worked the same as well.

Before I ever fired it, I read the owners manual, scoured the internet, read forums, and consumed every bit of information I could find. I poured over ChuckHawks article after ChuckHawks article. They were not very kind to the 700ML. I found most who had used the 700ML/MLS had high hopes going in but found it had less than desirable attributes as a muzzle-loader. Hence why my dad was able to pick one up at such a low price. The biggest problems I noted during my research:

1- #11 percussion caps are not as reliable and hot as 209 primers.

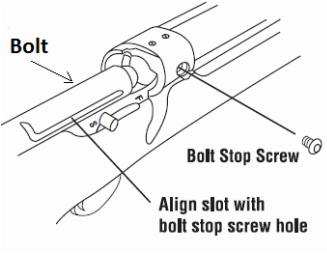

2- The bolt was held in by an Allen head screw with an un-threaded tip. It was easy to miss align, mangle the bolt and have a hard to work bolt.

3- Burning powder blows back through the percussion cap and into the bolt and action

(note 3 happens on side locks too, but the orientation of the lock and simplicity of the hammer make it less significant)

Black powder residue is corrosive. Blow back throughout the action caused the shooter to have to remove the bolt, disassemble and clean it after shooting the rifle. Failure to clean would certainly result in corroding the striker, spring, and inside of the bolt. Blow back got all over a scope, and some of the blow back could get into the trigger as well. To clean that, one had to remove the barreled action from the stock. This meant that one could possibly shift the zero after every cleaning. I had doubts as to how much, and made sure I used a torque wrench on each action screw. I then scribed a mark on each screw so that I could put them back with in the same tension after a field cleaning without a torque wrench. I didn’t know what more I could do. I wasn’t to concerned: I’d know if that was going to be a problem after a few range sessions.

The Savage design was taking over the market in the center-fire modified to muzzle-loader rifle. It had all the benefits and addressed some of the problems I had read about. But I had a free 700MLS in my hand and a desire to tinker. I knew I could and had to modify it.

I took the burs off of the tip of my Bolt Stop Screw with a file, and used a stone to work away the burs and abrasions on the bolt that I made when i misaligned and tightened up the screw. I lubed bolt and the slot the bolt stop screw rides in with anti-seize grease. No problems now, check off #2.

I also knew I had ‘better’ options than black powder. My dad had always used Pyrodex in his traditional side locks. I further researched and decided on Hodgdon Triple Seven. It was available in pellets and granular powder. It also was reported to be ‘less’ corrosive than black powder and Pyrodex, but still corrosive. I was suspicious of the claim of being “less corrosive” as a possible sales pitch. But when I realized Hodgdon made both Pyrodex and Triple Seven I wasn’t as worried; they had a solid reputation. I chose the granular powder because it was cheaper and allowed me to work up a load in smaller increments and see what my rifle would shoot best. For bullets, my research pointed me to MMP sabots and jacketed 45 caliber handgun bullets. I bought rings and put on a solid 4×32 scope.

The thing that really needed to go was the #11 percussion cap system. So off I went on my internet search to find a 209 modification for it. And at that time the pickings were slim on conversions (and still are). I found and purchased online what I’ll call a “Canadian” 209 kit. There really wasn’t any other 209 options. The kit came with a special tool to remove and replace the firing pin/striker with the included striker. It also had a new main spring, a 209 nipple to replace the #11 percussion cap nipple, and a fork to install the nipple and remove fired primers. Once I got the kit, I followed the instructions and I thought I had it whipped… but I really didn’t.

I went to the range and followed the Remington 700 ML/MLS Owners Manual as I worked up loads. I found that my rifle shot the best at 80 grains. Also there was still a bunch of blow back even at low charges, that worsened as I stepped up the load. As charges increased I started to find fragments of primers in the cavity around the primer holder. So, for many years I used 80 grains of Triple Seven, black MMP sabots, and .451cal 250gr Hornady XTP bullets. I deformed primers and had blow back, but the rifle was accurate at 80 grains. It was the best I could make of it; hotter loads weren’t an option.

I killed deer, cleaned the rifle, set the screws back to their scribe indexes and had no problems with point of impact shifts.

MY FIRST ATTEMPT (Canadian kit) WAS LESS THAN I HAD HOPED

I was disappointed with the amount of blow back I was getting, and the labor it took to take the rifle apart and clean it. I was always a bit worried I missed something in the bolt and would have a failure to fire at a critical moment… say when the shoulder of a Boone and Crockett trophy was in the cross hairs. Also, after shooting a deer, gutting it, and hauling it out of the woods, I was beat. The last thing I wanted to do was tear down a rifle and clean it. But I did.

I had to understand what was happening with the ‘Canadian’ 209 modification if I was going to do better. The replacement firing pin ended with a large cylinder that had a nipple that fired the primer. The ‘Canadian’ kit used the original OEM breach plug, but had the replacement 209 nipple threaded into it. It was a bit tricky to get a primer in and the kit came with a fork to remove the spent primer that was also the wrench to snug up the nipple into the breech plug. Extra tools to carry in the field didn’t sit well with me, but I put them in my possibles bag.

There was a small slot across the face for the fork to engage and a large cut out in the side for a spring to hold the primer in place. When cocked to fire, there was a gap between the striker face and the 209 primer. Nothing held the primer in place besides the spring on the nipple. Also the primer was exposed to the weather unless I used the OEM plastic cover. I had read that the weather shroud was not to be used with 209 primers somewhere, and had entered the land of operating outside the manual.

When the rifle fired, the striker sprung forward and struck the primer. With ignition came large pressures that blew the primer out and back against the face of the firing pin. With the firing pin being only held against the primer by spring pressure, the primer moves aft, unseats, and sprays blow back when discharged. Not to mention the nipple holding it was slotted so that pressure could blowout the three slots too. It was obvious why I was getting blow back, deformed and blown up primers. This explained why it worsened as I worked up powder charges.

So the Canadian 209 modification worked… but was messy, and the primer was exposed unless I took a perceived risk of adding the plastic weather shroud. The spring that held the primer in took a lot of abuse (and I’ve since learned they break and fail often). I also lost the plastic shroud on a hunting trip and had to purchase another. Plus the Remington 700 ML Owner’s manual says not to use the shroud with 209’s. I’ve seen plenty of reports of guys ignoring this warning and blowing up the shroud which then binds the bolt into the action. None of this set well with me.

I knew that my rifle returned to zero after I cleaned it. I killed deer, and never had a hang or a miss fire so long as I stayed on-top of the cleaning and maintenance, and didn’t hunt in the rain. I loved the trigger, and the feel. But I still wasn’t happy with the blow back and the required tedious maintenance.

I had to find a better way, so I again searched high and low. Eventually I found the best Remington 700ML 209 modification!

And that is the subject of my next Badger’s Den: THE REMINGTON 700ML/MLS, A JEWEL IN THE ROUGH; Can you make it shine? (PART 2)

Copyright BadgerRidgeInd.com 2015 (originally posted at BadgerRidgeInd.com)

Copyright Badger-Ridge.com 2024 (Edited, improved and reposted here)