I’m embarrassed, but I’ll admit it: I’m disorganized and inefficient compared to what I expect of myself.

I like to work on all sorts of things, but I don’t invest the time and thought I should into organizing and cleaning up. I frequently finish a project, but fail to really ‘finish’ it by putting all the tools that got drug out back where they belong. Eventually when I need those same tools, I then cannot find them. Along the way I’ve bought a bunch of different sets of box end wrenches, and frequently grab more onesie-twosie at swap-n-shops. I occasionally have to cut weld or bend one to make a custom wrench for a specific job. So I have multiples of the same size in all sorts of lengths. When I need one of them, I typically have to stop and think about the last project I completed with that tool, and then begin searching the locale where that project was done. Or dig through the pile in the respective tool drawer.

I have resolved to do better. I know that the foundation of being organized is having a place for everything, then making sure to put everything back in its place. And to that end, I went around the shop and started gathering all the loose wrenches, screw drivers, pliers etc. When I pulled out the drawers of my tool chest and tossed them all in, I realized I had only just begun.

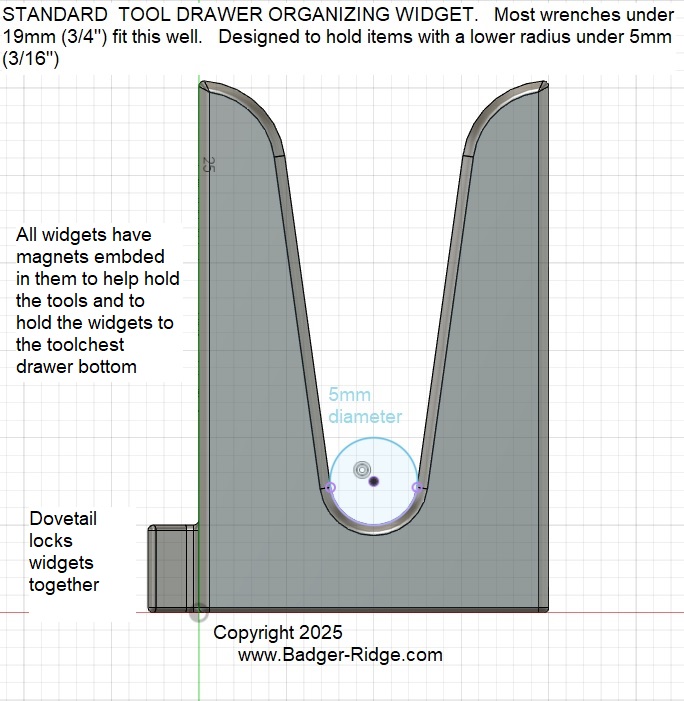

That’s when inspiration hit me. I wanted to get started organizing, but of course, I had a whole bunch of other things that I had to get done before I could act on that inspiration. I turned those obligations into opportunities to continue working out in my mind what I was thinking of doing. Where I wanted to end up. Once I’d cleared my obligations out of the way, I rewarded myself with some time ‘CADing’ out what I had in my head for a tool drawer organizing widget:

At first I realized I had to keep it simple: just tackle all the box end wrenches that continually floated around. I knew that I didn’t want to make an investment into designing a “perfect” large organizer that I’d have to change and reprint once I bought new tools, or a different tool chest. I needed something flexible, that would adapt with changes in the work shop. So I decided a small flexible modular approach was best. I knew I wanted a magnet in the organizers to help hold the tools in their proper place. That’s what I “cadded.”

Then once I had the widget in my hand and I began to use it, I realized that I needed more than one size, that I wanted to follow the convention of metric-Blue, inch-red, and that these same widgets could organize many different types of tools. Along the way I think I got my box end & flare nut wrenches the way I want (at least for now):

Now I just have to make myself put these wrenches back in their proper place when I’m done with the project that draws them out of the drawer. I also want to come up with a flexible labeling system, but really I’m not sure I’ll invest more time to that end: Just knowing where the 10mm and a few other sizes are by setting them off with different colors, seems to do enough that I’m not spending all the time I used to digging through the drawer looking for a specific size. I find what I need fast now.

So how does all this affect you? We’ll I’m glad to explain it to you! First I’m offering this tool organizing widget solution for sale here at Badger Ridge. You too can organize your tool chest drawers in an effective and flexible manner. First you need to appreciate that these widgets have magnets in them. They want to stay where you put them in your tool chest drawer. You’ll be best served if three or more are snapped together to get much greater stability than a single widget. Also with the magnets, metal tools want to stay in them, but aren’t so stuck that its work to get a tool of of them. Second the widgets snap together and apart if you need to re-arrange them, and again for stability, you probably want to plan on having 3 or more widgets snapped together.

Also, before you buy you probably want to understand what sizes are available and what purpose they will probably serve. Let’s start with the standard widget:

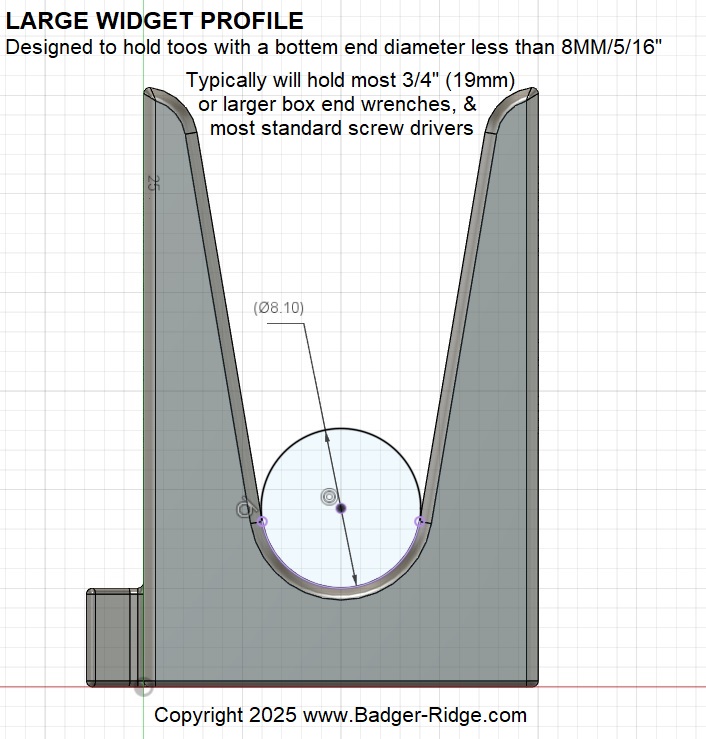

The standard widget holds wrenches smaller than 1″ (25mm), and does great with screw drivers with smaller shafts. However I’d plan on wrenches over 3/4″ (19mm) to fit better in a “large” widget:

Also I’ve found that standard screw drivers sit better in the large widget.

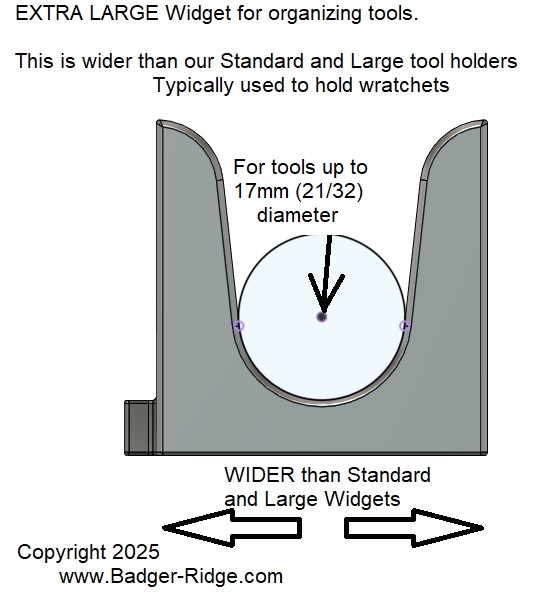

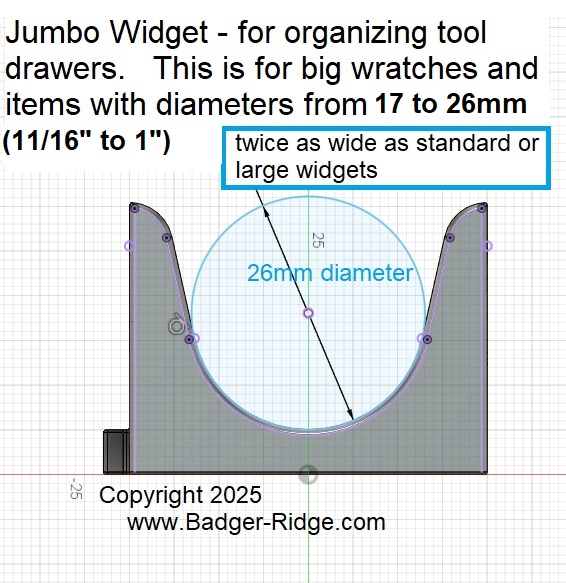

When I moved on to my drawer of ratchets I realized I needed a couple of different larger widgets. The standard and large widget have the same foot print, only their mouths had different profiles. But to hold the larger shafts of my 3/8″ and 1/2″ ratchets (bot standard and telescoping), I needed to make two larger widgets. I called them XL & Jumbo (see below)

The jumbo is double the width of the standard/large widgets, it holds my telescoping ratchets & 3/4″ drive ratchet. The XL widget is in between the Jumbo & the Standard/Large and holds my standard 3/8″ ratchets well.

So ignoring wrenches, if stuff to be held is under 5mm in diameter, use a standard widget. If its over 5mm but under 8mm, a large widget. Between 8 and 17mm, use and XL widget. Over 17mm, but un 26mm use a Jumbo.

In summary, let me break it down for you like this. If I was organizing a tool chest I’d count things in the following manner. First I’d go through and count all the wrenches. I’d break them down into two groups: how many below 19mm (3/4″) and above 19mm. I’d then break those into metric counts (for blue), and inch counts (for red). You might want to adjust these for using grey for 10mm etc… color choices are up to you.

For each wrench smaller than 19mm (3/4″) get a Standard Widget

For each wrench 19mm (3/4″) or larger get a Large Widget

Then segregate and count your remaining screw drivers, nut drivers, ratchets, extensions, etc, measuring at the diameter of the portion that would rest on the widget. Sort them by under 8mm, over 8mm, but under 15mm, and over 15mm.

For each screwdriver/nut driver with a shaft under 8mm driver get a Large Widget.

For each extension, and ratchet handle under 8mm (probably only 1/4 drive) get a Large Widget

For each screw driver, nut driver, etc., with a shaft 8mm (5/16) or larger get an XL Widget

For each extension, and each ratchet with a shaft over 8mm up to 17mm get an XL widget

For each extension & ratchet over 17mm (but under 26mm) diameter get an Jumbo widget

For each telescoping ratchet and 3/4″ ratchet (certainly will be over 17mm diameter) get a Jumbo

For each hammer handle (over 17mm diameter get a Jumbo

This has been an effort that had yield great rewards in organization and efficiency. I hope you have a similar pleasant experience making your tool chests do more for you. To get started putting these widgets in your cart please click here.

If you have a 3D printer and would like to purchase a personal use license to print our tool widgets, please click here.