If you came here looking for muzzle-loader solutions, you are at the right website, and probably will need to click one of the banners or hotlinks here, or just go to ‘Our Products.’

For today’s Badger’s Den installment I’m going to discuss a new product to help those who shoot Remington VersaMax shotguns.

Observant customers will find that most of our products follow my hobbies and activities. Living a quiet life and working with my hands has been my ambition for quite some time. Once I retired from wearing a uniform, that became more of a reality. At that same time that I retired, we found a nice place in the woods of Michigan’s thumb. I was blessed to spend more time in the fields, waters, and woods chasing game than I had previously. So I’ve succeeded in putting quiet a few rounds through my favorite hunting guns these last few years. When need a shotgun I grab my VersaMax, unless its a walk around all day sort of hunt (like for pheasant).

On a conservation snow goose hunt out west, my previously 100% reliable VersaMax began to let me down. I began to have repeated intermittent misfires. I’d categorize them as light primer strikes as when I examined the shells removed from the chamber, they had light dents in the primer. When I put the same shells (with the light primer dent) in another shotgun they went bang. So I knew something had changed with my otherwise super reliable VersaMax. I stumbled around looking for insight and solutions. I eventually came to understand the shotgun’s shortcomings and how to fix them. So I still use and love my VersaMax, and I hope to share with you a few products that can help you to keep loving and using yours.

Before I talk more about the new action/recoil spring we’ve made for the VersaMax, let me quickly recap the 3 areas that tend to produce the light strike/failures to fire in these guns.

1: The bolt cam pin and bolt carrier interface is commonly bad. Remington left burs from milling the cam slot, and the original cam pins don’t last. So pull your bolt/bolt carrier assembly apart and examine these parts closely. Remove any burs, buff out any gouges, and replace a deformed cam pin

2: Remington missed the mark on the hammer spring cap/plunger: mine was chrome plated. The chrome plating was chipping off. It make an abrasive crud that worked away at the ‘pot metal’ casting of the trigger group and bound the hammer up. Then once I cleaned and removed the crud the edge of the chrome would still grab the trigger housing and cause the hammer to hick-up and hang-up.

I removed the original cam pin, hammer, hammer spring and plunger and replaced them with Benelli parts. We call our kits with these four parts “Remelli” kits…. Benelli parts in a Remington shotgun. This works because the VersaMax is a Benelli clone (for the most part). The Benelli parts seem to last a lot longer while improving reliability.

3. We finally get to discuss the new part we offer: VersaMax Action Springs. All springs wear out. Spring life is measured in cycles. A full cycle is a compression to its minimum working length then release to its maximum length. Note that leaving a hammer cocked… or a magazine loaded is essentially half of a cycle. Releasing the spring is the other half… that’s why its an old wives tale that you shouldn’t leave magazines loaded, or hammers cocked. That’s not true! It’s the cycles that matter, and releasing the pressure is half of what increases the wear! Re compressing the spring is the other half. So Leaving stuff cocked/loaded doesn’t hurt a spring!

Each cycle takes a small bit of ‘push’ out of the coil spring. Eventually the cycles will reduce the force the spring produces to a point that the mechanism becomes unreliable. Again its not the length of time the spring is compressed… it’s the number of cycles that wears out a spring!

In the VersaMax, main spring issues are further aggravated because the owner’s manual doesn’t advise one of the need to remove and clean the action/recoil spring and it’s plunger. Because the manual doesn’t direct you to service it, you may not realize that this spring resides in a tube in the buttstock. The bolt carrier’s ‘rat tail’ engages the action spring’s plunger. And with each cycle of the bolt, it subjects this spring to a cycle. Again, a cycle is one compression followed by a release.

To properly clean and maintain the action spring, we have to regularly remove the spring and clean the plunger, tube, and spring. Then lightly lube with gun-oil (CLP, RemOil, etc), and reassemble. The Remington owner’s manual doesn’t tell us this! If we omit this service, the crud that builds in the tube and on the plunger, coupled with a lack of proper lubrication, will further rob the recoil spring of pushing force. And once enough crud builds up, or it gets too dry, or the spring looses enough push from cycles, the gun becomes unreliable. This is because the recoil/action spring must push the bolt fully closed or the gun cannot go bang. Or in other words this spring must push the bolt & bolt carrier fully forward into full battery or the gun will not be reliable.

Once I took care of 1 & 2, and began diligently cleaning the recoil/action spring, I got reliability back… at least until my shotgun’s original spring wore totally out (about 100-150 rounds after I took care of 1&2 and cleaned/lubed the recoil spring).

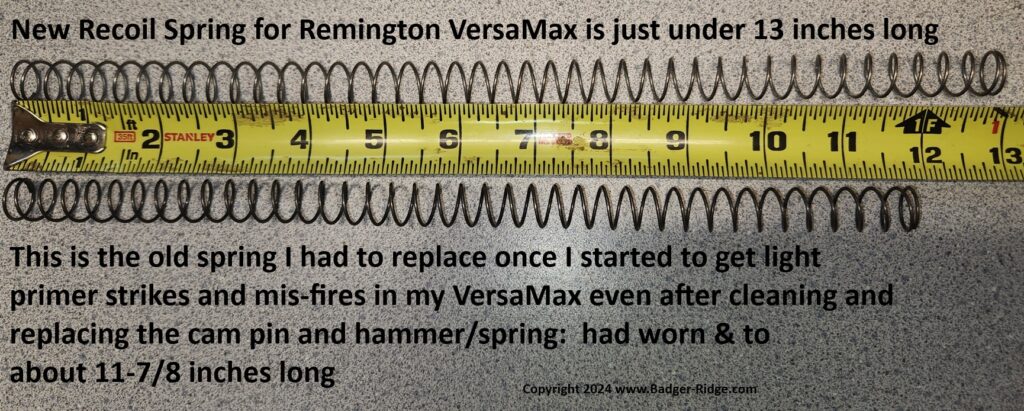

So we bought and sold Remington made VersaMax action springs. When they became unattainable, I began to examine the Remington original spring’s construction, and dusted off my limited understanding of spring design. I enlisted the help of USA engineers who specialize in springs, and we’ve produced (in the USA) a replacement spring that has the same “push” force as the original factory spring, but will do it for considerably more cycles. (I’ve been told to expect near double the cycles, but that will prove out over time.)

When it comes to springs, some folks and some vendors seem to treat them like they are magic or that they have special materials in their springs. Springs are not magical, and there isn’t any special fairy dust that get’s you more out of spring. Springs, like all things, are devices that have trade offs. Pushing harder (ie getting a ‘higher power’ spring) also has it’s trade offs. Quite simply, we improved this springs function by better using the space in the recoil spring tube to push just as hard, but for more cycles. We did it by spending a little more on better craftsmanship and production methods (like setting the springs)… and a little bit more metal per spring. Its just a better design made better here in the USA: no special fairy dust & no exotic spring materials needed.

Just remember: all springs wear out. We are confident our VersaMax recoil/action springs (F4011305IMP) will work just the same as the factory original, but for longer (ie more cycles).

WE DON’T JUST SELL THESE SPRINGS! WE USE THEM TOO!